How can I better control part weight and thickness on a horizontal injection molding machine?

In the injection molding industry, maintaining consistent part weight and thickness is crucial for ensuring product quality, reducing waste, and optimizing production efficiency. Horizontal injection molding machines are equipped with advanced features that enable manufacturers to control these critical parameters better. By fine-tuning process variables such as injection speed, pressure, and temperature, horizontal injection molding machines can help manufacturers produce parts that meet stringent quality standards and dimensional specifications.

The Role of Injection Speed and Pressure in Weight Control on Horizontal Injection Molding Machine

One of the most important factors in controlling the weight and thickness of molded parts is the injection speed and pressure settings on the horizontal injection molding machine. Injection speed determines how quickly the material enters the mold cavity, while the pressure applied during injection influences material flow and fill density. Both variables are crucial for achieving the correct part weight and ensuring uniform thickness.

By adjusting injection speed and pressure, manufacturers can control how the material fills the mold. Higher injection speeds and pressures enable the injection of more material into the cavity, which is crucial for producing thicker parts. Conversely, you can use lower injection speeds and pressures for parts with thinner walls, better controlling part weight and minimizing material waste.

The Impact of Barrel and Screw Design on Part Consistency in Horizontal Injection Molding Machines

The design of the barrel and screw in a horizontal injection molding machine is crucial for maintaining stable material flow, which results in uniform part weight and thickness. A well-designed screw ensures that you fully melt and evenly mix the plastic material before injecting it into the mold. Screw geometry affects material delivery, plasticization, and injection patterns.

Stable melt quality is crucial for achieving consistent part weight and thickness. Uneven material melting or inconsistent viscosity can lead to defects such as inconsistent part thickness or weight. Advancedinjection molding machine, equipped with specialized screws designed for specific applications, help optimize material flow and improve consistency. Variable speed drives and precise temperature control further enhance screw performance, enabling manufacturers to maintain optimal melt conditions for each part.

Advanced temperature control systems ensure consistent molding.

Temperature control is another key factor in controlling part weight and thickness during the injection molding process. Precise regulation of melt, mold, and barrel temperatures is crucial to ensure stable material flow and good solidification. Horizontal injection molding machines are often equipped with advanced mold temperature controllers to maintain a stable and precise temperature profile throughout the molding process.

Stable mold temperature helps ensure uniform cooling of the part, which directly impacts part thickness. Uneven cooling can cause warping or shrinkage, ultimately resulting in non-compliant parts. Horizontal injection molding machines help avoid these defects by precisely controlling melt and mold temperatures, ensuring parts are molded to the desired weight and thickness. Advanced injection molding machines may be equipped with multi-zone temperature control systems to manage temperature variations throughout the mold, further improving part dimensional consistency.

The Role of Material Selection in Controlling Part Weight and Thickness

The materials used in the injection molding process are crucial to achieving the desired part weight and thickness. Different materials have unique flow characteristics, shrinkage rates, and thermal properties, which impact the molding process. Horizontal injection molding machines offer the flexibility to process a wide range of materials, from standard thermoplastics to more specialized composites, ensuring that the selected material meets the desired part specifications.

By selecting the appropriate material for the application, manufacturers can better control part weight and thickness. For example, materials with low shrinkage and high flow properties are ideal for producing parts with uniform thickness. You can also add customized additives to modify flow properties or reduce shrinkage during cooling, further controlling the dimensions of the final product.

Real-Time Monitoring and Feedback for Precise Control

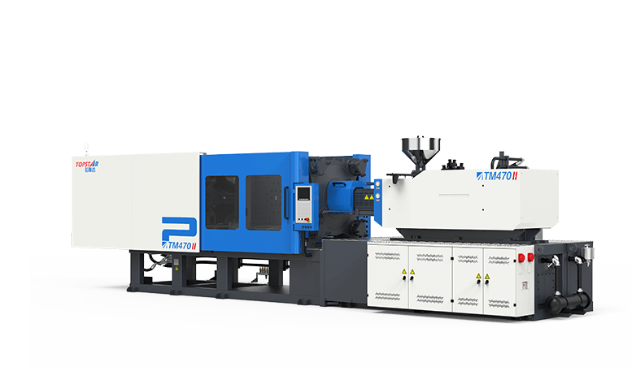

One of the key advantages of Topstar horizontal injection molding machines is their ability to provide real-time monitoring and feedback during the injection molding process. These machines use sensors and advanced control systems to track critical parameters, including injection pressure, mold temperature, material flow, and part weight. This continuous monitoring enables manufacturers to make immediate adjustments, ensuring consistent part weight and thickness. These machines typically include closed-loop control systems that automatically adjust injection speed, pressure, and temperature based on real-time data. This real-time feedback loop helps prevent deviations in part weight and thickness, ensuring that every part produced meets the specified requirements.

Achieving Precise Control of Part Weight and Thickness

Horizontal injection molding machines offer a range of advanced features and technologies that enable precise control over part weight and thickness. By utilizing advanced temperature control systems, screw and barrel designs, real-time monitoring, and customizable settings, manufacturers can produce consistently high-quality parts that meet precise specifications. These injection molding machines offer the flexibility and controllability to produce parts of various sizes while reducing material waste and increasing overall efficiency.