Progressive Dies Techniques That Reduce Waste in High Volume Production

High-volume production challenges manufacturers to optimize efficiency and minimize material waste. Progressive dies address these challenges effectively. By combining multiple operations into a single sequence, manufacturers can reduce scrap and increase output. This approach also enhances precision and consistency across all components. Understanding these techniques is essential for factories seeking sustainable and cost-effective operations. Progressive dies streamline production while maintaining high-quality standards. They play a pivotal role in modern manufacturing. Progressive dies are crucial for efficiently reducing waste.

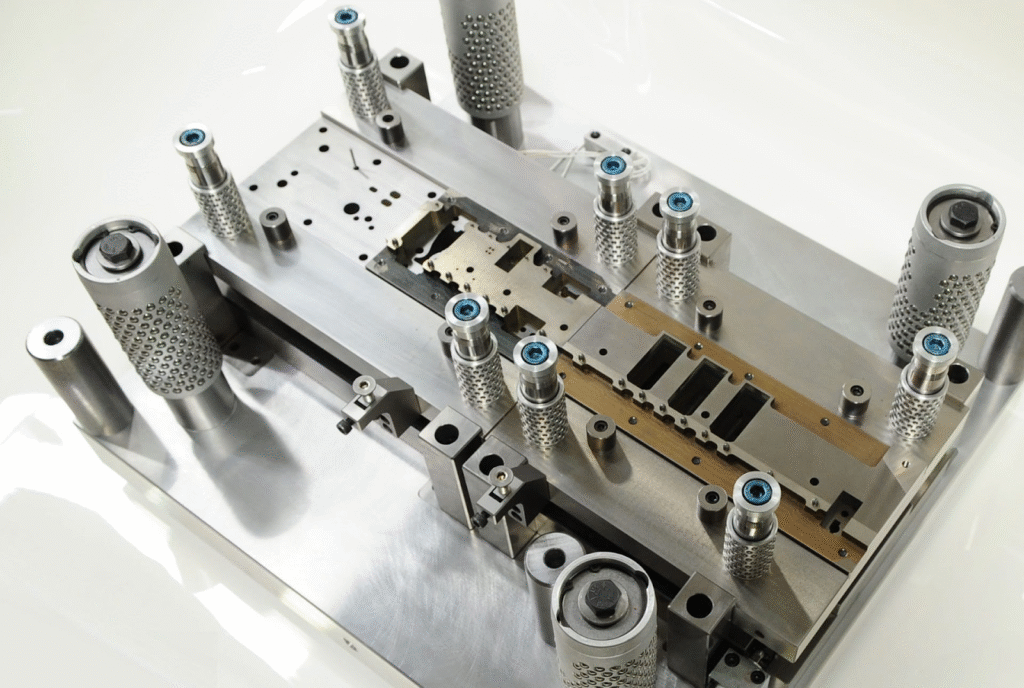

Streamlined Material Usage

Modern progressive dies allow multiple operations on a single metal strip. This reduces leftover scrap and material costs. Engineers design layouts to maximize metal utilization. Fewer interruptions in the production process enhance speed. Efficient material use aligns with sustainability goals. Manufacturers achieve both economic and environmental benefits. Material optimization remains a key advantage of progressive dies. Progressive dies improve resource utilization in production.

Reduced Cycle Times

Progressive dies perform punching, bending, and forming in a continuous sequence. This reduces production cycle times significantly. Faster cycles lead to higher throughput and lower labor costs. Reduced idle time ensures better machine utilization. Continuous operations maintain uniformity in component quality. Quick cycles help meet tight deadlines without sacrificing precision. Cycle time reduction is a significant trend in progressive dies. Progressive dies enhance high-volume production efficiency.

Precision and Consistency

High-volume production demands consistent dimensions and tolerances. Progressive dies maintain accuracy across thousands of parts. Precision reduces rework, scrap, and assembly errors. Consistent components improve overall product reliability. Uniformity is crucial for automotive, electronics, and industrial applications. Advanced design and manufacturing techniques ensure dies stay precise. Precision and consistency define modern progressive dies. Progressive dies deliver reliable component quality.

Integration with Automated Production Lines

Progressive dies integrate seamlessly with automated manufacturing systems. Robotic feeders transport strips efficiently between stations. Automation reduces manual handling and increases safety. Integrated systems maintain consistent speed and output. Real-time monitoring allows predictive maintenance and reduces downtime. Automation compatibility boosts overall operational efficiency. Integration is a defining feature of modern progressive dies. Progressive dies support fully automated production workflows.

Cost Savings and Efficiency

Reduced scrap, faster cycles, and lower labor needs translate into cost savings. Progressive die allow manufacturers to invest in innovation rather than rework. Less material waste lowers purchasing costs and disposal expenses. Operational efficiency strengthens profit margins without compromising quality. Manufacturers can scale production more sustainably. Cost-effectiveness is a critical benefit of progressive dies. Progressive dies enhance financial and operational performance.

Rapid Prototyping and Flexibility

Progressive dies facilitate rapid prototyping of new components. Designers can test layouts and adjust dies quickly and efficiently. Flexibility in design supports product customization without slowing production. Faster prototyping improves time-to-market for new products. Iterative adjustments ensure optimized material usage and precision. Manufacturers respond quickly to changing market demands. Flexibility is a growing trend in progressive dies technology. Progressive dies support adaptive production strategies.

Durability and Maintenance

High-quality progressive dies are durable and withstand high-volume operations. Precision machining and robust materials reduce wear and tear. Predictable maintenance schedules minimize unplanned downtime. Long-lasting dies ensure continuous, reliable production. Durability protects investments and supports consistent quality. Manufacturers benefit from predictable performance and extended die life. Maintenance efficiency is key for progressive dies in high-volume production. Progressive dies provide reliable and durable service.

Conclusion on Progressive Dies

Progressive dies techniques reduce waste, improve precision, and enhance production efficiency. They streamline material usage, lower costs, support automation, and allow rapid prototyping. Durable and flexible dies ensure sustainable, high-volume manufacturing. Manufacturers that adopt these techniques gain competitive advantages in terms of speed, quality, and profitability. Progressive dies remain central to modern industrial fabrication strategies. Their ongoing innovation ensures more efficient and reliable production processes. Progressive dies are crucial for reducing waste in high-volume production.