Understanding Reflow Soldering in SMT PCB Assembly

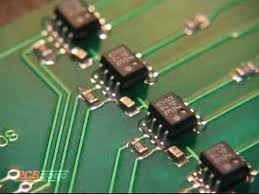

In the high-speed world of electronics manufacturing, creating a secure and reliable bond between components and printed circuit boards (PCBs) is essential. One of the most critical steps in this process is reflow soldering — a method that uses controlled heat to melt solder paste and attach surface-mount devices (SMDs) to the board. Whether it’s for consumer electronics, automotive systems, or medical devices, SMT PCB assembly relies heavily on precise reflow soldering to achieve the performance and durability required in today’s products.

This article will guide you through the principles of reflow soldering, the equipment involved, process stages, common challenges, and how manufacturers ensure high-quality results.

What Is Reflow Soldering?

Reflow soldering is a thermal process used in Surface-Mount Technology (SMT) to permanently attach components to the PCB. After components are placed onto solder-pasted pads, the assembly is passed through a reflow oven. Inside the oven, controlled heating profiles cause the solder to melt (reflow), form strong joints, and then cool to solidify the connections.

Compared to manual soldering, reflow soldering offers:

- Consistency – Each joint receives the same heating cycle.

- High Throughput – Capable of processing hundreds or thousands of boards per day.

- Precision – Reduces risk of overheating sensitive components.

The Reflow Soldering Process

Reflow soldering isn’t just about applying heat — it’s a carefully timed sequence designed to protect components while ensuring optimal solder flow. The process is divided into four main stages:

1. Preheat Stage

- Purpose: Gradually raises the PCB temperature to prevent thermal shock.

- Details: The temperature increases at a controlled rate (typically 1–3°C per second) until it reaches a level where flux activation begins.

2. Soak Stage

- Purpose: Activates the flux in the solder paste, which removes oxides from component leads and pads.

- Details: The board is held at a stable temperature (usually between 150–180°C) for 60–120 seconds.

3. Reflow Stage

- Purpose: This is the peak heating stage where the solder melts and forms the final bond.

- Details: Temperatures rise above the solder alloy’s melting point (around 220–250°C for lead-free solder), but exposure is kept short to prevent component damage.

4. Cooling Stage

- Purpose: Solidifies the solder joints and prevents defects like grainy structures or cracks.

- Details: Rapid, controlled cooling ensures strong metallurgical bonds.

Types of Reflow Soldering Equipment

Manufacturers use different types of ovens depending on their production needs and budget:

- Infrared (IR) Reflow Ovens – Use IR lamps to heat the PCB. Best for smaller production runs.

- Convection Reflow Ovens – Use heated air for uniform heating; widely used in mass production.

- Vapor Phase Reflow Ovens – Provide extremely uniform heating by immersing the board in vapor from a boiling liquid; ideal for complex assemblies.

- Hybrid Ovens – Combine IR and convection methods for maximum efficiency.

Common Reflow Soldering Defects

Despite being highly automated, reflow soldering can still encounter issues if parameters are not optimized:

- Tombstoning: One end of a component lifts off the board due to uneven heating.

- Solder Balling: Tiny balls of solder scattered around pads, usually caused by excessive flux or poor paste printing.

- Voiding: Air pockets inside solder joints, which can weaken the connection.

- Cold Joints: Result from insufficient heat, leaving solder dull and weak.

Preventing these defects requires precise control over the heating profile and careful preparation of the PCB and solder paste.

Quality Control in Reflow Soldering

Leading SMT manufacturers employ strict quality assurance measures:

- Thermal Profiling: Each new assembly run begins with creating an optimized heating profile using thermocouples to monitor temperature at various PCB points.

- Automated Optical Inspection (AOI): Detects misaligned or missing components after reflow.

- X-Ray Inspection: Checks hidden solder joints under Ball Grid Array (BGA) components.

- Oven Maintenance: Regular cleaning prevents contamination that could impact heat transfer.

Advantages of Reflow Soldering in SMT PCB Assembly

Reflow soldering plays a critical role in modern electronics manufacturing:

- Supports Miniaturization – Works perfectly with small SMDs for compact designs.

- High Reliability – Produces strong joints that withstand vibration and temperature changes.

- Automation-Friendly – Integrates seamlessly with pick-and-place machines for fully automated production lines.

- Scalable Production – Equally efficient for small prototypes and high-volume manufacturing.

The Future of Reflow Soldering

As devices continue to shrink and performance demands rise, reflow soldering technology is advancing:

- Nitrogen Atmosphere Reflow – Reduces oxidation during soldering for higher quality joints.

- Closed-Loop Control Systems – Use sensors to adjust heating in real time.

- Energy-Efficient Ovens – Reduce manufacturing costs and environmental impact.

- Integration with Industry 4.0 – Data from reflow ovens is shared across the production line for predictive maintenance and process optimization.

Conclusion

Reflow soldering is more than just a heating step — it’s the backbone of successful SMT PCB assembly. By providing consistent, high-quality solder joints, it enables manufacturers to meet the growing demands for smaller, faster, and more reliable electronics. With ongoing innovations in oven technology and process control, reflow soldering will continue to be a driving force behind the electronics of tomorrow.